Pillow Plates

Pillow Plates

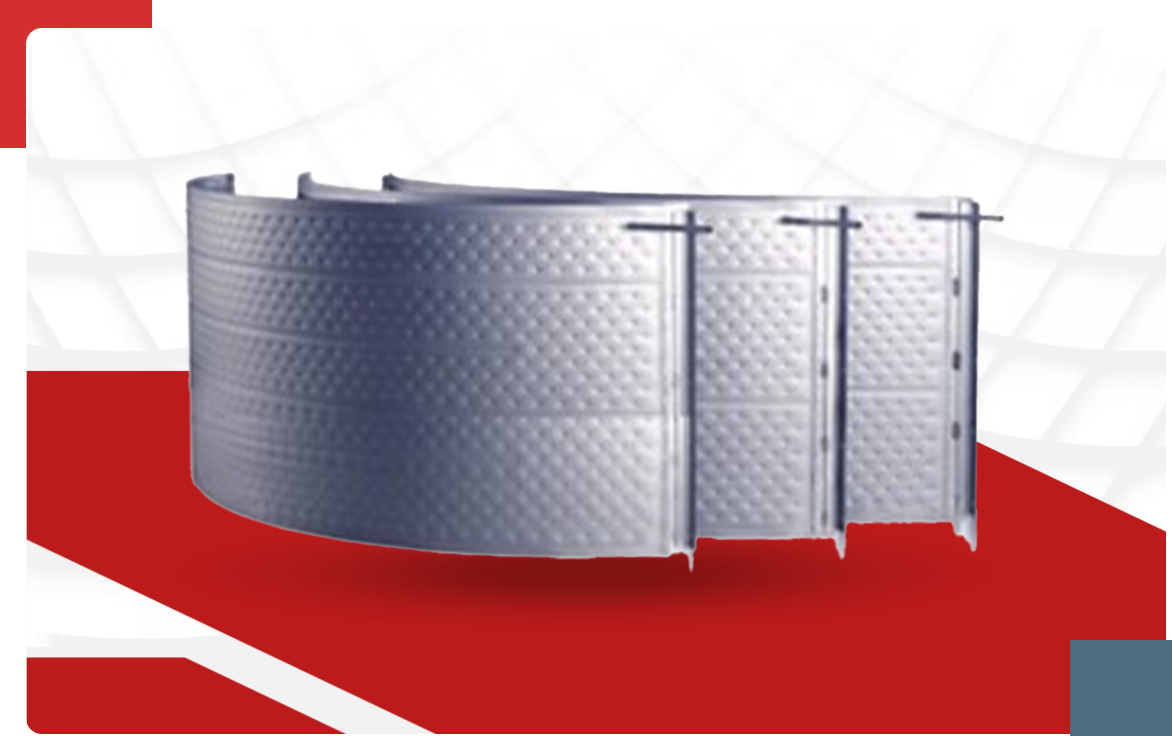

Pillow Plates are a remarkable innovation in the realm of heat exchangers, and Micro Coils Products boasts an extensive track record in their manufacturing. These laser-welded plates offer limitless possibilities for industrial cooling and heating across diverse product types and industries.

Endless Applications

Micro Coils’ Pillow Plates are at the heart of countless industrial processes. With their exceptional versatility, they find applications in various sectors. Notably, Pillow Plates are employed in the manufacturing of different types of BMC (Bulk Milk Cooler) products and vessels, demonstrating their adaptability and efficiency.

Ideal for Cooling

In industries such as milk, soft drinks, wine, or beer, precise cooling is paramount. Micro Coils Pillow Plates are the go-to choice for ensuring optimal temperature control in these industries. They play a crucial role in maintaining the quality and integrity of these products, making them indispensable components in the world of industrial cooling.

Versatile Applications Beyond Expectations

Meat Processing Industry

Chemical Industry

Pharmaceutical Industry

Oil & Gas Industry

Main Advantages of Using Micro Coils Pillow Plate

Micro Coils Pillow Plate offers a plethora of advantages that make them the preferred choice for various industrial applications. Here are the key benefits of using our Pillow Plate products:

Large Opening Lids for Easy Access

Our Pillow Plates are designed with large opening lids, facilitating convenient access for maintenance and cleaning. This feature ensures thorough cleaning, promoting hygiene and efficient operation.

Stainless-Steel Body

We use top-grade stainless steel (304 and 316 SS) for our Pillow Plates. This stainless-steel body acts as a robust barrier, protecting products such as milk from harmful bacteria, viruses, and fungi.

Cost-Effective and Economical

Micro Coils manufactures cost-effective Pillow Plate products by leveraging low laser welding costs while ensuring high-pressure bearing capacity. This approach enables you to achieve efficiency without breaking the bank.

Thinner Material with Strength

We utilize thinner materials in our Pillow Plate products to reduce material consumption without compromising strength and efficiency. This not only saves resources but also minimizes environmental impact.

Reduced Fouling

The efficient welding design pattern minimizes the deposition of algae, lime, and other contaminants due to higher turbulence. This reduction in fouling results in cleaner, more efficient operations.

Advanced CNC Manufacturing

Micro Coils employs advanced CNC machines for laser cutting, welding, and other manufacturing processes. This versatility allows us to produce Pillow Plates in various shapes and configurations, meeting your specific requirements and ensuring customer satisfaction.

24x7

Customer Support

1.0 M

1.0 Million coils can be Manufactured Annually

90,000

Sq. ft. Campus of Manufacturing Facility

40%

Employees are Engineers & Domain Experts

Connect With Us

Connect with Us to Explore Possibilities and Shape Innovations.